Simon Wilson said:

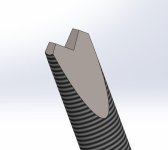

I know around half a dozen people who have ended up in hospital using capping rods. A great deal has been learned about the design of capping rods and Pete Hall's rods are based on a lot of combined experience. Silver steel with a hardened and tempered tip ground to a slightly hollow chisel point has proved to be the best. Also, lightweight rods are dangerous. The rod needs to be at least a metre long and needs to have some mass, I guess around a couple of kilos.

Capping is dangerous.

There are things you can do to limit the danger.

I have taken the view that the greatest danger is from shattered rock and bits of brass casings, hence the need for a decent sized piece of conveyor belt rubber over the area.

Presumably a heavy capping rod is to add some inertia to prevent the rod firing back out. I mitigate this by attaching the pin to a rubber handled bolt driver, which I hold firmly with my hand through the strap. I always try to make sure I am not in line with the hole, though sometimes this is unavoidable. I am happy that this limits the chance of injury from the pin to an "acceptable" level.

I've not seen anybody else using this technique and perhaps there is a good reason? So far, it seems very effective and I have not had any concerns or near misses, but I don't do that much capping.

I would also think the length of the bar will need to depend on the cave situation. What is the reasoning for 1m long? Is this just to add weight, or to get further away from the action?