The Old Ruminator

Well-known member

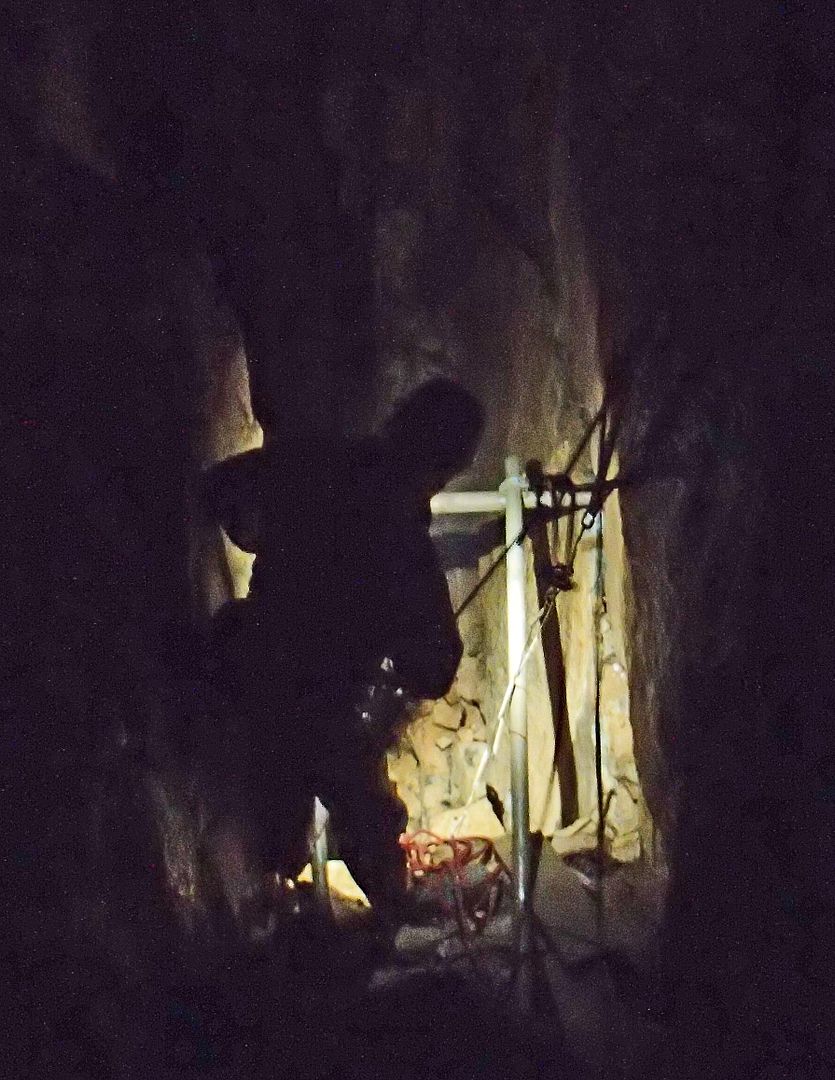

Usually we use steel poles but are aluminium poles stable in the long term in a cave environment ? I know they oxidise but that is suppose to add a protective coating. Tried the web but not convinced either way.

bograt said:I thought most stainless was pretty electro - inert?, worked for me in many environments, anyway.

TheBitterEnd said:Electrically isolating dissimilar metals will help, e.g. if you use a steel clip on a ali tube you could wrap the tube in electrical tape (or paint it).

SamT said:... the force applied by a clip is more than likely going to cut through tape/paint and damn it - you have a circuit and you've got electrolytic action again.