langcliffe

Well-known member

topcat said:The split pitch yes? As it seems common to have problems here, do you know if the issues arise when not splitting the pitch, or does the rope tend to jam even if you split at the ledge?

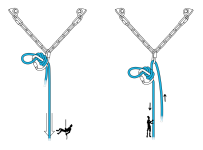

A karabiner is only required when belaying the rope round a scaffold pole or a wooden beam as it allows the the rope to lock when tightened. When using P-bolts, however, a karabiner become a liability as it can rise up and get jammed on the P-bolt.

All one actually needs is a very thick knot which won't pass through the bolt. The bigger the knot, the better...

We have never had even a momentary problem since dispensing with karabiners about ten years ago.