Apologies if the points below appear pedantic, but people read threads like this and take away the exact wording as their understanding, so the words need to be as accurate as possible even if those who understand the physics know what was meant without them. So I'm happy to be corrected if my words aren't perfect.

Dry, static friction is dependent only on the force between the surfaces and the coefficient of friction, contact area isn't significant, nor is rope deformation. I would agree, however, that more bend in the rope is associated with more force, and therefore more friction.that more krab is in contact with the rope, so friction increases

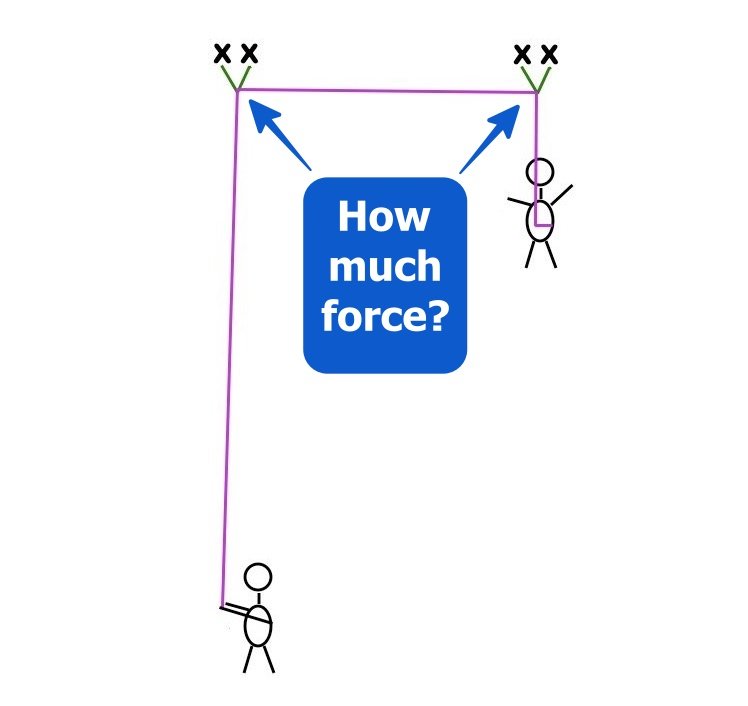

If the deviation cord bisects the angle of the bend in the rope, it's effectively totally frictionless. The tension in the rope, in that situation, is symmetrical relative to the krab, and the deviation cord is inline with the resultant force and can't carry anything but axial load, so there's no path for any friction force to be transferred. It would be accurate to say that "the main anchor load is 100% in a frictionless system or one with the same geometry". In practice, the cord won't be positioned to exactly bisect the angle, so there will be a friction force, which could be up or down.The main anchor load is only 100% in a frictionless system