You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolting ethics underground and overground

- Thread starter rog saxton

- Start date

Steve Clark

Well-known member

I wonder if the pull test was done directionally to replicate a fall? Or even if it possible to do that?

Direct pull-out test I believe, so not representative of slightly eccentric shear from a fall. In the same ballpark of load though, given that it was only 150kg to failure and the peg didn't pull-out, it failed in the thin bit of metal around the eye-hole. Can't zoom in enough to see the fracture surfaces, but the description was :

"The loop where you would clip was fully corroded when I looked at cross sections and riddled with micro fractures throughout. (Likely held a few falls)"

Contrast this with another description from a very experienced climber on the same thread :

"The peg was chrome moly not mild steel. It wasn’t rusted through and was in pretty good condition when I checked it. I tried to replace but it wouldn’t move and appeared solid throughout"

Clearly appearances can be deceptive.

In answer you your question about testing direction, I guess you could test it by loading it up from below with test weights or in tension against another set of bolts lower down. Much simpler to test in pull-out with a high factor of safety.

(Photo below taken by Stuart Holmes published on facebook, with the new bolt and the peg has now been fully cut off)

Attachments

langcliffe

Well-known member

Sorry - that makes even less sense to me than your previous posting. I'll that down to my lack of education as well.you will if you were to read more on the subject. that's not intended as a keyboard warrior slur, but an honest statement. but that aside, I was merely implying that if I were a detective challenged to solve the mystery, a caver is where I'd start. but even that wasn't the purpose of the post, but only the explanation of why I posted here. the purpose was to offer education to the uneducated.

you will if you were to read more on the subject. that's not intended as a keyboard warrior slur, but an honest statement. but that aside, I was merely implying that if I were a detective challenged to solve the mystery, a caver is where I'd start. but even that wasn't the purpose of the post, but only the explanation of why I posted here. the purpose was to offer education to the uneducated. As a climber and caver I find the assumptions of many climbers of cavers and vice versa often ridiculous, unfounded, amusing, but mostly sad. Reading some of these replies reminds me firstly why I mostly avoid forums and secondly that once people enter their chosen silo, they're mostly stuck there for life.

or maybe the point is that it was simply wrong and maybe if people understood that then the person in question will perhaps find out if he does indeed turn out to be a caver. and regardless, all cavers who read this may learn a little or may want to ask experienced climbers to explain the argument, if they can't initially see it. someone bolting a top rope anchor to play around on a very easy route and identifying as a climber is like someone doing repeated trips into the churns and sell gill plus little else and calling themselves a caver. best not to brand people like that. I'm sensing in the defensive whataboutery maybe there's a concern that climbers generally are blaming cavers. I've no idea, but I doubt it as not that many climbers go caving. But it is a truism that climbers haven't used spit anchors for probs 40 years. I'm not particularly old, but like a lot of cavers, have a spits and hangers in my caving cupboard.

cavemanmike

Well-known member

Looking at that picture you will get a micro nut on the right hand side of that crack

Mark

Well-known member

You can stick your ethics up your arse as far as I'm concerned

www.ukhillwalking.com

www.ukhillwalking.com

UKH Forums - Climbing in caves

Last edited:

Steve Clark

Well-known member

Looking at that picture you will get a micro nut on the right hand side of that crack

It looks like it it might, but I think it's actually quite a blunt arete at that point. 60 deg rather than 90 so you can't get behind the crack and it would sit sideways and not really work.

If this was some hard route on natural grit, there's no way it would even have the peg in it and would be an effective solo just like dozens or hundreds of others in the Peak & Yorkshire. It's just one of the better routes in the quarries that works for mere mortals with one bit of artificial gear placed on the first ascent in 1968.

As hinted above, it's all a bit arbitrary. One of the most famous routes on the grit, Masters Edge at Millstone is protected by narrow headed cams that happen to fit in shot-holes left behind by the quarrying. The face is artificial, the shot holes are artificial, the ground below the route has been levelled and rocks removed to provide a safe landing, there's dozens of videos showing how to do the moves and people abseil down it before hand to pre-mark the holds with chalk, practice the moves (head-pointing). People have fallen off below the shot holes and broken their back. Anyone getting past the hard bit above the shot holes and not falling off is back in easier solo territory at 60ft up.

If someone put an extra bolt in Masters Edge it would be viewed with the outrage of demolishing the Lancaster hole colonnades with a sledgehammer.

The Colonades may possibly also be artificial - lots of limestone was worked in the area...

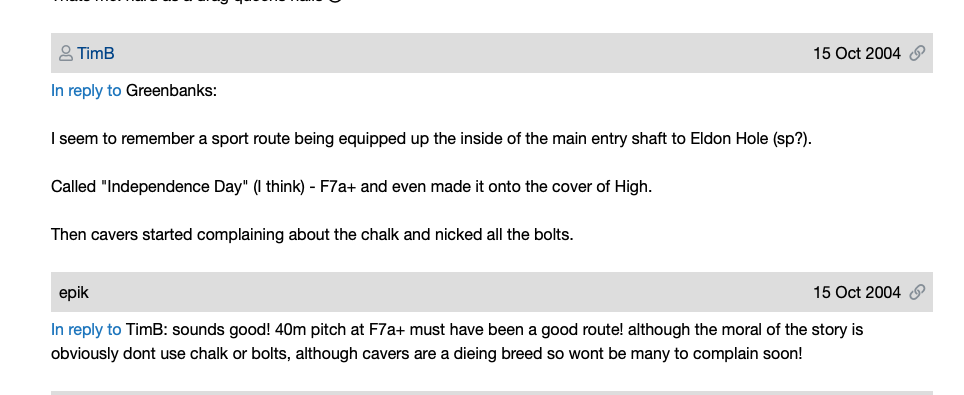

Mind you, the last time that something similar happened, it did appear to be cavers: https://ukcaving.com/board/index.php?threads/bolting-ethics.18765/

Mind you, the last time that something similar happened, it did appear to be cavers: https://ukcaving.com/board/index.php?threads/bolting-ethics.18765/

a couple of bolts on a lump of quarried rock.....shock, horror......I think the land owner should bolt and start charging in these times when agcriculture has to diversify

I'd look at climbers or ex climbers first. Not as if they (we) haven't caused enough issues at Almscliffe in recent years:

litter

uncontrolled dogs

shitting

bouldering and using spot lamps - shining directly into the farm house. For years we climbed (we bimbled upward) in winter boots and headtorchs in winter. Never a poblem as we were considerate and didn't annoy the land owner.

I can see a day when climbers own actions get a ban at Almscliff

I'd look at climbers or ex climbers first. Not as if they (we) haven't caused enough issues at Almscliffe in recent years:

litter

uncontrolled dogs

shitting

bouldering and using spot lamps - shining directly into the farm house. For years we climbed (we bimbled upward) in winter boots and headtorchs in winter. Never a poblem as we were considerate and didn't annoy the land owner.

I can see a day when climbers own actions get a ban at Almscliff

Cantclimbtom

Well-known member

Anyone wanting to climb a route with the "brown adrenaline" of a suspect peg can simply clip the replacement with a £3 Chinese carabiner from ebay described as ideal for: camping, climbing, caving, repelling (sic), dog walking.

Stu

Active member

No...Isn't almscliff on open access land? - which means the owner can't ban climbing...