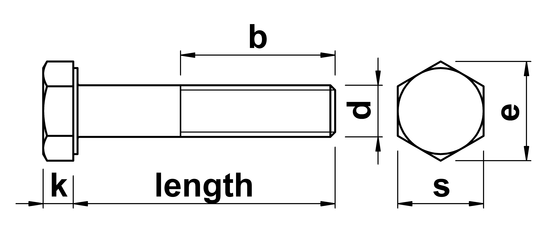

In a moment of unthinking idiocy a while ago I binned the bolts for all the Troll/Lizard hangers I have because they looked a bit old and rusty. I put in some stainless set screws. Then I realised this was a total cock because the shoulder has to land on the spit sleeve, not the plastic bit becoming compressed. A standard bolt has a thread that is twice as long as needed. Does anyone know where to get a 25mm bolt length where the thread (b) is more like 10mm? Material can be zinced 8.8/10.9 or any stainless. The only alternative I can see is to hack off the end of a 35mm bolt, and I don’t want to do that for this. Or I bin them all, which looks likely now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom bolt for hangers

- Thread starter Fjell

- Start date

Loki

Active member

what's wrong with squashing the plastic a bit? the bolt/screw doesn't need to be super tight?

you could get them custom made, but this would likely be a cut thread, whereas rolled threads are better

or buy some alloy tube and cut it up to make spacers, to replace the plastic bits

is zinc plated kinder to the spits? stainless is hard, and creates galvanic corrsions

you could get them custom made, but this would likely be a cut thread, whereas rolled threads are better

or buy some alloy tube and cut it up to make spacers, to replace the plastic bits

is zinc plated kinder to the spits? stainless is hard, and creates galvanic corrsions

No, you would have to drill the hanger. Did think about it before.

I do think the bolt needs to land, otherwise you just keep distorting everything including the little alloy plate. I am also a bit paranoid about the bolt going too far into the spit sleeve.

I did consider threaded tube, but it is rapidly becoming an epic for 15 hangers. Same with sawing off 15 bolts as that will be difficult to end up with a bolt end that works easily and won’t corrode immediately. I didn’t think it would be so hard to find a simple bolt with a shorter thread, I have looked.

Wayland Smith

Active member

Are you really still using Spits? Or is this clickbait?

Many of the spit caves are hidden gems and well worth the effort........Are you really still using Spits? Or is this clickbait?

JAshley73

Member

Could you post the complete bolt/expanding nut/sleeve/hanger that you're looking at?

I'm a machinist by trade, do design work for my day-job, and am fairly well versed in industrial hardware. I may be able to find something.

Side Note: Here in the USA, we have an online/catalog supplier McMaster-Carr. If they don't have it, it probably doesn't exist. I'm not sure if there's a British/European counterpart, but it's a fantastic resource for industrial hardware, and the website against which all others should be judged...

www.mcmaster.com

I'm a machinist by trade, do design work for my day-job, and am fairly well versed in industrial hardware. I may be able to find something.

Side Note: Here in the USA, we have an online/catalog supplier McMaster-Carr. If they don't have it, it probably doesn't exist. I'm not sure if there's a British/European counterpart, but it's a fantastic resource for industrial hardware, and the website against which all others should be judged...

www.mcmaster.com

It looks like this. Originally the shoulder of the bolt was beyond the plastic bit. I am going to replace the plastic with the sleeve above and lock it. Should be OK. Only discussion is whether to use 25 or 30mm bolt. The thread exposed should be same as a normal hanger I think because I don’t want the bolt to land on the end of the spit thread inside, just in case something is in there that might impact the wedge. These hangers have been unobtainium for decades.Could you post the complete bolt/expanding nut/sleeve/hanger that you're looking at?

I'm a machinist by trade, do design work for my day-job, and am fairly well versed in industrial hardware. I may be able to find something.

Side Note: Here in the USA, we have an online/catalog supplier McMaster-Carr. If they don't have it, it probably doesn't exist. I'm not sure if there's a British/European counterpart, but it's a fantastic resource for industrial hardware, and the website against which all others should be judged...

www.mcmaster.com

Leclused

Active member

Last edited:

JAshley73

Member

The bottom photo is pretty helpful in describing what you want to do. Based on your eBay photo, I'm assuming that you're using an M8x1.25 screw, and need the spacer to be 12mm long.It looks like this. Originally the shoulder of the bolt was beyond the plastic bit. I am going to replace the plastic with the sleeve above and lock it. Should be OK. Only discussion is whether to use 25 or 30mm bolt. The thread exposed should be same as a normal hanger I think because I don’t want the bolt to land on the end of the spit thread inside, just in case something is in there that might impact the wedge. These hangers have been unobtainium for decades.

View attachment 18369

Typical design parameters for threaded connections, is you want 1.5xDiamter in thread-length engagement. So for an M8 screw, you want the threads to be 12mm+ deep. I'm not sure how deep your female-threaded anchors are.

Ass_u_ming that your hanger plate is 2.5mm thick. (+/- .5mm ...) You need a screw that's 2.5 + 12 + 12 = 26.5mm+ long .

Based on that, my recommendation would be...

Hex Head Screws, 316 Stainless

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Button Head Screws, 316 Stainless, Passivated

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

If you're ok with either 11mm or 15mm long spacers, I'd recommend these. If you need something closer to 12mm long, go with an "Inch" sized spacer for 5/16" screws, and either 7/16" (11.1mm) or 1/2" (12.7mm) long. The inch sizes are more expensive though. (I have no idea why...)

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

"Ass_u_ming that your hanger plate is 2.5mm thick. (+/- .5mm ...) You need a screw that's 2.5 + 12 + 12 = 26.5mm+ long" .

----------------------------------

I have a "lizard" caving hanger for an M8 bolt but unfortunately no bolt

The plate is exactly 3mm thick made from aluminium pressed to shape with the name

I think "Troll" made a similar item called a "bollard" but don't quote me on that

I remember the hanger in use slightly compressed the rope which would make the plastic spacer 10mm long??? -

Final bolt length will depend on your rope thickness and if you want a trapped or loose rope on the hanger

I would agree with the above bolt length calculation using 1.5 x Bolt dia which should avoid pushing the wedge out

Any small difference in bolt length availability could be adjusted by a washer between the bolt and hanger

This would be good practice anyway to avoid the corners of the "steel" bolt scraping the softer aluminium hanger

----------------------------------

I have a "lizard" caving hanger for an M8 bolt but unfortunately no bolt

The plate is exactly 3mm thick made from aluminium pressed to shape with the name

I think "Troll" made a similar item called a "bollard" but don't quote me on that

I remember the hanger in use slightly compressed the rope which would make the plastic spacer 10mm long??? -

Final bolt length will depend on your rope thickness and if you want a trapped or loose rope on the hanger

I would agree with the above bolt length calculation using 1.5 x Bolt dia which should avoid pushing the wedge out

Any small difference in bolt length availability could be adjusted by a washer between the bolt and hanger

This would be good practice anyway to avoid the corners of the "steel" bolt scraping the softer aluminium hanger

There is a washer, and yes I have concluded it’s not a standard length for a M8 bolt (25 or 30mm). I have plenty of both in stainless (boats eh?). I will try both with the stainless spacer. I am intending ultimately to use red threadlock, which should be enough to stop it moving. Cutting a stainless bolt will be a vale of tears to get a decent end. The bolt needs to be for a 13mm spanner.

JAshley73

Member

Re: Cutting - Stainless hardware isn't "hard". It's on the lower end of the Rockwell hardness scales, and is no tough task with even a hack-saw.

That said, it's not too expensive to buy either.

FWIW, Someone mentioned shoulder bolts earlier, and for posterity's sake - I would advise strongly against them.

The 90* angle from the threads to the shoulder is the weakest point when you are loading them in shear. All of the load flows through this "corner" and it will break here every time. No way I would trust my life to a shoulder screw for this use.

A standard screw of the same length is much stronger with the same load applied.

That said, it's not too expensive to buy either.

FWIW, Someone mentioned shoulder bolts earlier, and for posterity's sake - I would advise strongly against them.

The 90* angle from the threads to the shoulder is the weakest point when you are loading them in shear. All of the load flows through this "corner" and it will break here every time. No way I would trust my life to a shoulder screw for this use.

A standard screw of the same length is much stronger with the same load applied.