You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help wanted - EN 959 testing

- Thread starter IanWalker

- Start date

Bob Mehew

Well-known member

Simple answer is no. Fischer had a good downloadable booklet which gave some back ground but I think it no longer is on their web site and I can't find my copy. There is a write up on BCA's approach in the BCA Equipment & Techniques Committee minutes of 5 April 2014 at page 4 item 8, see https://british-caving.org.uk/documents/et-minutes-05-04-14/?tmstv=1700428158 . Simply put, it requires a sufficient number of samples tested to show that there is a statistical justification for claiming the axial or radial strength values.

Loki

Active member

I’ve not read that specific standard but if it’s like any of the other ppe standards then only one sample is required to be tested by a third party. There are then two routes to ensure production quality- either the manufacturer sends items for test on a regular basis OR they have an audited quality system e.g. iso 9001 and the onus is then on the manufacturer to ensure all products meet the requirements of the standard. Not sure if that helps in this instance!

Thanks both, this is super helpful.

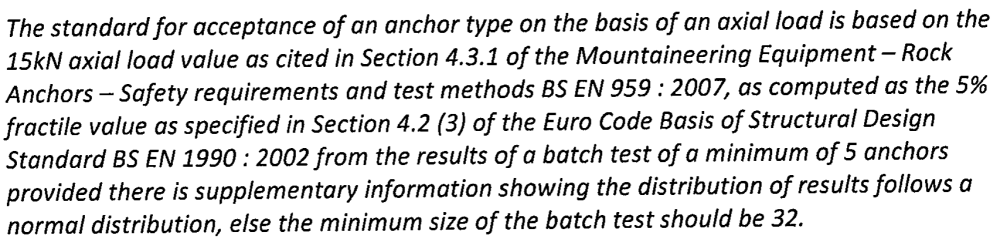

@Bob Mehew raised the BCA approach. The BCA adopted its own protocol for accepting anchors using an axial test:

From BS EN 1990 it chose a characteristic value based on statistical analysis and 5% fractile value. It seems there are other methods of choosing a characteristic value too. Interesting that BCA chose axial only (which doesn't meet 959) and 15kN (which doesn't meet UIAA 123).

But this isn't coming from BS EN 959, which is what my question referred to.

The meeting document refers to Simon Wilson's IC anchor testing. The doc on the CNCC website seems to follow the BCA standard above, with the addition of rotational and radial tests (one of each). Which suggests it meets BS EN 959 even though the sample size is one in each case. The IC anchors were axially tested in limestone (not concrete per 959) which is explained in the text.

Its clearer to me now, having read the above, how the BCA cherry picked from recognised standards. The other thread about rope standards and selecting appropriate equipment even if not CE marked springs to mind. But this wasn't intended to be a thread about the BCA scheme.

@Loki Are anchors PPE? I'm not sure. But it makes sense that where recognised quality systems are already in place that they are used.

Still looking for anyone to add to the discussion on BS EN 959 - it would be appreciated. Thanks

@Bob Mehew raised the BCA approach. The BCA adopted its own protocol for accepting anchors using an axial test:

From BS EN 1990 it chose a characteristic value based on statistical analysis and 5% fractile value. It seems there are other methods of choosing a characteristic value too. Interesting that BCA chose axial only (which doesn't meet 959) and 15kN (which doesn't meet UIAA 123).

But this isn't coming from BS EN 959, which is what my question referred to.

The meeting document refers to Simon Wilson's IC anchor testing. The doc on the CNCC website seems to follow the BCA standard above, with the addition of rotational and radial tests (one of each). Which suggests it meets BS EN 959 even though the sample size is one in each case. The IC anchors were axially tested in limestone (not concrete per 959) which is explained in the text.

Its clearer to me now, having read the above, how the BCA cherry picked from recognised standards. The other thread about rope standards and selecting appropriate equipment even if not CE marked springs to mind. But this wasn't intended to be a thread about the BCA scheme.

@Loki Are anchors PPE? I'm not sure. But it makes sense that where recognised quality systems are already in place that they are used.

Still looking for anyone to add to the discussion on BS EN 959 - it would be appreciated. Thanks

Mark Wright

Active member

BCA should join the BSI and get all the relevant standards purchased at half price and always have the most up to date versions.

This claims to be a free copy of 2018 standard (haven't actually checked it's veracity):

About me on website claims:

About me on website claims:

EN 959-2018 pdf download - Free Standards Download

EN 959-2018 pdf download.Mountaineering equipment - Rock anchors - Safety requirements and test methods.

www.freestandardsdownload.com

Digital Millenium Copyright Act:Hello, my name is John Smith. I just graduated from university and now I work in Australia. My work is related to engineering and construction, so in my spare time I often collect some useful standards, hoping that they can help you.

All the resources of this website are uploaded freely by netizens from all over the world. If any content violates the DMCA or your copyright, please contact the administrator of this website, and I will delete it within one working day.

E-mail address is:myskywhitecloud@gmail.com

Pete K

Well-known member

I'd be cautious of clicking anything like that. The digital standards from BSI are heavily copy protected and I can't even print one off more than 3 times on my licence. Chances are anything 'free' is an expired version of the standard or it might just be there to fish for your details or implant something nasty on your PC. I don't have the current 959, but even if I did, the software and licence prevents me sharing it.

Bob Mehew

Well-known member

Off the theme but for information, BSI charge £186 for EN 959 badged by them (or £93 if you are a member). Estonia standards charge 13.20 euros for EN 959 in English and badged by them (pdf version). How many standards cavers are interested in which are not EN based? Oh, also some libraries still offer access to BSs. I will come back on the theme late today as I am now off on another job.

georgenorth

Active member

Hi Ian,Thanks both, this is super helpful.

@Bob Mehew raised the BCA approach. The BCA adopted its own protocol for accepting anchors using an axial test:

View attachment 17487

From BS EN 1990 it chose a characteristic value based on statistical analysis and 5% fractile value. It seems there are other methods of choosing a characteristic value too. Interesting that BCA chose axial only (which doesn't meet 959) and 15kN (which doesn't meet UIAA 123).

But this isn't coming from BS EN 959, which is what my question referred to.

The meeting document refers to Simon Wilson's IC anchor testing. The doc on the CNCC website seems to follow the BCA standard above, with the addition of rotational and radial tests (one of each). Which suggests it meets BS EN 959 even though the sample size is one in each case. The IC anchors were axially tested in limestone (not concrete per 959) which is explained in the text.

Its clearer to me now, having read the above, how the BCA cherry picked from recognised standards. The other thread about rope standards and selecting appropriate equipment even if not CE marked springs to mind. But this wasn't intended to be a thread about the BCA scheme.

@Loki Are anchors PPE? I'm not sure. But it makes sense that where recognised quality systems are already in place that they are used.

Still looking for anyone to add to the discussion on BS EN 959 - it would be appreciated. Thanks

Anchors intended for permanent installation (which is what you’re interested in I assume?) are not considered PPE. PPE is classed as equipment which is “intended to be worn or held by a person”. For example a carabiner is classed as PPE, but a safety handrail is not. HTH.

G.

@Mark Wright raises an interesting point. Do we know if the BCA have a copy of the standard (2007 or 2018)? And might it be available for BCA members to use?

I dared to click the link but it didn't workThis claims to be a free copy of 2018 standard (haven't actually checked it's veracity):

EN 959-2018 pdf download - Free Standards Download

EN 959-2018 pdf download.Mountaineering equipment - Rock anchors - Safety requirements and test methods.www.freestandardsdownload.com

This is super useful .Off the theme but for information, BSI charge £186 for EN 959 badged by them (or £93 if you are a member). Estonia standards charge 13.20 euros for EN 959 in English and badged by them (pdf version). How many standards cavers are interested in which are not EN based? Oh, also some libraries still offer access to BSs. I will come back on the theme late today as I am now off on another job.

EVS-EN 959:2018

Mountaineering equipment - Rock anchors - Safety requirements and test methods

It does say that documents will be removed if copyrighter complains.I dared to click the link but it didn't work

Another allows you to see the index, list of changes since 2007 (although not the details) & definitions, before purchase:

My query relates to concrete screws in recreational use.Anchors intended for permanent installation (which is what you’re interested in I assume?) are not considered PPE. PPE is classed as equipment which is “intended to be worn or held by a person”. For example a carabiner is classed as PPE, but a safety handrail is not. HTH.

They I think are intended to be permanent in an industrial setting. And they could be left in a cave for anyone to use (i.e. not personal).

But they are easily removable so it would be feasible to be used for a short time only by one person and then removed. OR short term use by multiple people, known or unknown. I don't know quite what the implications are of this use case. Does it mean a temporary anchor doesn't need to meet EN959 at all? Would people consider meeting EN959 to be sufficient assurance for a short-term use by multiple people?

The nearest thing I can think of it the Petzl Pulse removable anchor. The 12mm version has multiple certifications for permanent and temporary installation, if I googled the standards correctly. But these are industrial standards and I'm not sure this helps.

- Certification(s): CE EN 795 B, CE EN 959, TS 16415, GB 30862/B, UKCA

- Certification(s): CE EN 795 B, CE EN 959, TS 16415, GB 30862/B, UKCA

Last edited:

Anything you put 5-8cm into native rock is going to be exposed to defects. Concrete is a homogenous material you can replicate and test. If you are putting a rock bolt 2-3m into rock, the risk of defects tends to even out. We choose to use bolts in rock by analogy to concrete testing. It’s OK if the rock is homogenous, but since we can’t prove it we say you need to use two independent anchors to reduce the risk to negligible. It has worked to date.

The Petzl Pulse is a removable spit, and I think the reality is that no manufacturer is going to say that is OK these days for sport climbing as a single failure could lead to death or injury.

The Petzl Pulse is a removable spit, and I think the reality is that no manufacturer is going to say that is OK these days for sport climbing as a single failure could lead to death or injury.

No anchors need to meet BS EN959. There are very few BS or EN standards which are required by law in the UK (not the case in some other countries). The standards represent good practice as determined by a committee of experts from the user and manufacturer community for the standard in question. Installers and manufacturers may comply with the standards they consider appropriate and (as in the other thread) can then state that they comply.Does it mean a temporary anchor doesn't need to meet EN959 at all?

If you plan to use concrete screws, the question should be not whether they can meet EN959, but whether the specific screw you plan to use has been tested for the use you intend, or if not, for a use which you are confident is sufficiently similar. See for example the European Technical Assessment for one of Fischer's products:

Testing the capacity for static loads doesn't necessarily mean that capacity will be available for dynamic loads, even if the peak force is the same.

Testing the capacity for static loads doesn't necessarily mean that capacity will be available for dynamic loads, even if the peak force is the same.

I have tested them - in a fashion - my query is to assist with interpretation of the results. I'm looking for context of other anchors and anchor testing methods.If you plan to use concrete screws, the question should be not whether they can meet EN959, but whether the specific screw you plan to use has been tested for the use you intend, or if not, for a use which you are confident is sufficiently similar.

I understand this. EN959 and the BCA scheme use static (or at least slow pull) tests for their anchor testing which gives me confidence it is an widely accepted compromise in this case.Testing the capacity for static loads doesn't necessarily mean that capacity will be available for dynamic loads, even if the peak force is the same.

That being said, I have been considering some dynamic (drop) testing and how/where would be best to do this.

Chocolate fireguard

Active member

This is the sort of statement sometimes seen about the performance of ropes under static and dynamic load.the capacity for static loads doesn't necessarily mean that capacity will be available for dynamic loads, even if the peak force is the same.

Except the word "necessarily" is not usually there, and neither are the last 8 words.

Which suggests that you know something about when an impulsive load is really just a static one that isn't there for very long!

I have always thought that it must be something to do with how long the force pulse is compared with the time for the stress waves to travel throughout the parent material.

If that is so then the couple of hundred milliseconds load pulse duration for someone falling onto a rope (cows tail?) is plenty of time for the stresses in the nearby rock/concrete to reach the same state as in the static load.

Do you have any references for this sort of stuff? I haven't been able to find anything.