tomferry

Well-known member

Hello all I no we have lez and a couple other old mining engineers on here, I was wondering someone could help us out with a couple questions .

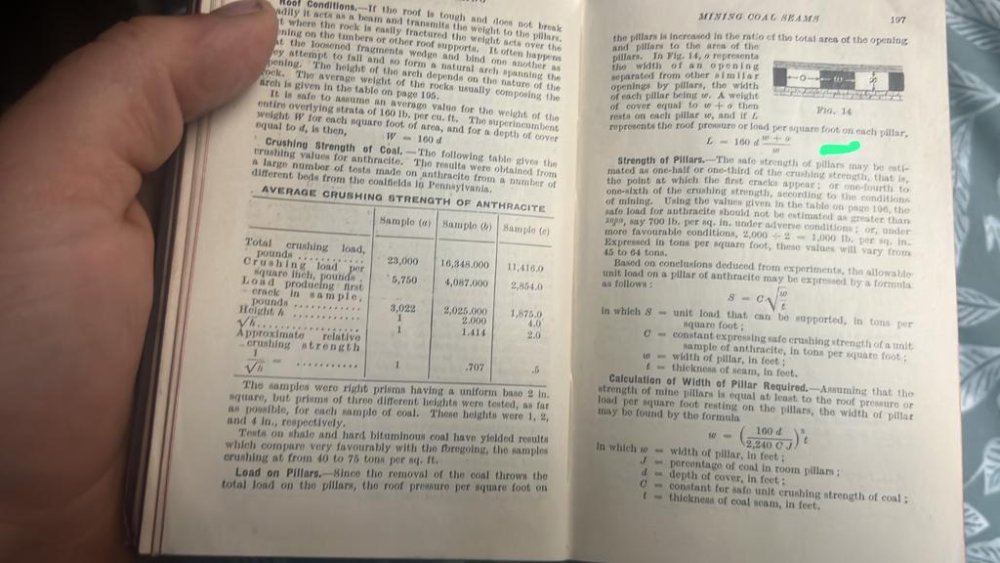

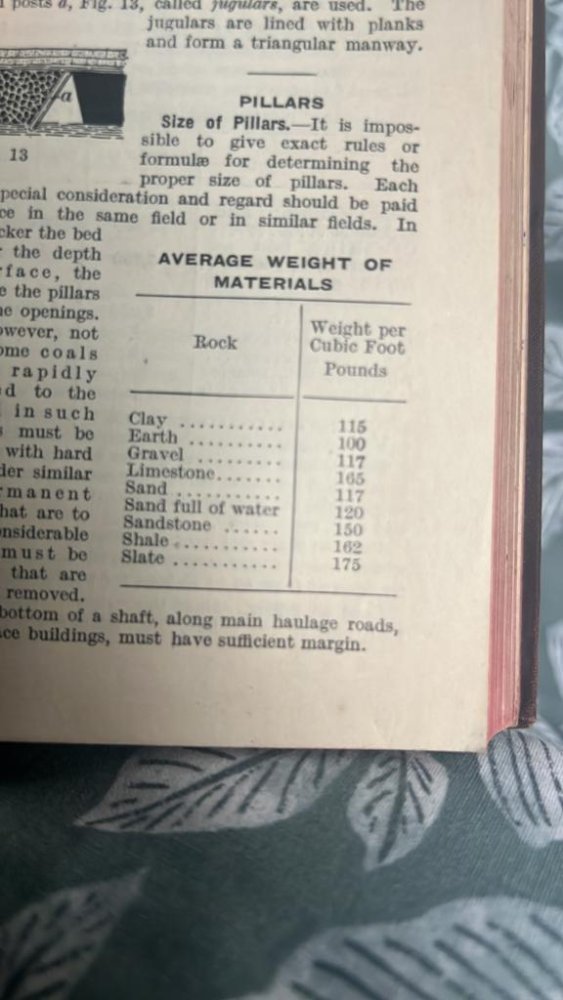

Maths question highlighted in green this has caused large amounts of conversation in our mining Mondays club . You will need to view the second image also .

Other question is I believe with wooden roof tells you hammer them in loosely , when passing if you feel the need you wiggle them to check they are not tight . If they are tight this means the roof is dipping and time to insert a prop . Other people in our club say they will drop onto the floor !! Myself I have never heard of this can some one knowledgeable teach us about this ??

I can see with the steel pins there is a chance if the crack grows they would drop out ? But surely this would mean the roof would dip and pinch it tight on the other hand

We need some one of knowledge!

Maths question highlighted in green this has caused large amounts of conversation in our mining Mondays club . You will need to view the second image also .

Other question is I believe with wooden roof tells you hammer them in loosely , when passing if you feel the need you wiggle them to check they are not tight . If they are tight this means the roof is dipping and time to insert a prop . Other people in our club say they will drop onto the floor !! Myself I have never heard of this can some one knowledgeable teach us about this ??

I can see with the steel pins there is a chance if the crack grows they would drop out ? But surely this would mean the roof would dip and pinch it tight on the other hand

We need some one of knowledge!