Not cave related but looks like it is in limestone - Diamond Handline North Wales

[Alex Rhodes] dropped into the Diamond on the falling tide this afternoon. The hand line is compromised on the green slab, just as you start to lose height down to the boulders.

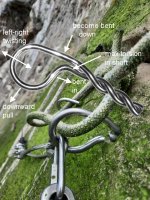

The glue-in bolt has cracked on its underside rendering both maillons at risk of detaching completely and either handline before/after coming free. If someone was fully weighting either cable via their lanyards, that wouldn’t be a nice outcome.

There’s a second glue-in next to it linked by some tat, but this doesn’t back up the hand lines as the maillons aren’t incorporated.

I’ve stuck a bail biner linking the two maillons for now – worst case if the bolt blows completely, the two wires are still connected by something. Still would be a nasty shock for someone not expecting it!

BMC rep and NW Bolt Fund notified

Link to post: https://www.facebook.com/share/p/bGGtR3WvRT1a3iVw/

[Alex Rhodes] dropped into the Diamond on the falling tide this afternoon. The hand line is compromised on the green slab, just as you start to lose height down to the boulders.

The glue-in bolt has cracked on its underside rendering both maillons at risk of detaching completely and either handline before/after coming free. If someone was fully weighting either cable via their lanyards, that wouldn’t be a nice outcome.

There’s a second glue-in next to it linked by some tat, but this doesn’t back up the hand lines as the maillons aren’t incorporated.

I’ve stuck a bail biner linking the two maillons for now – worst case if the bolt blows completely, the two wires are still connected by something. Still would be a nasty shock for someone not expecting it!

BMC rep and NW Bolt Fund notified

Link to post: https://www.facebook.com/share/p/bGGtR3WvRT1a3iVw/