tomferry

Well-known member

Hello everyone

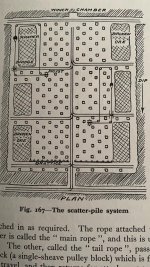

Have been reading metalliferous mining by s higham it is a very good read to say the least if your into learning about how stuff works and was designed in great detail.

I have asked a few people and these appear to be quite rare and not a a great deal known about them I am going to kindly ask Chris to attach a couple of photos for how it explains they are used etc

My question is if anyone has seen these on the journeys out could you please say where or if their sensitive sites feel free to private message .

Or any useful information would be great to have added into the thread .

Regards Tom .

Have been reading metalliferous mining by s higham it is a very good read to say the least if your into learning about how stuff works and was designed in great detail.

I have asked a few people and these appear to be quite rare and not a a great deal known about them I am going to kindly ask Chris to attach a couple of photos for how it explains they are used etc

My question is if anyone has seen these on the journeys out could you please say where or if their sensitive sites feel free to private message .

Or any useful information would be great to have added into the thread .

Regards Tom .