You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill Review

- Thread starter maxf

- Start date

pwhole

Well-known member

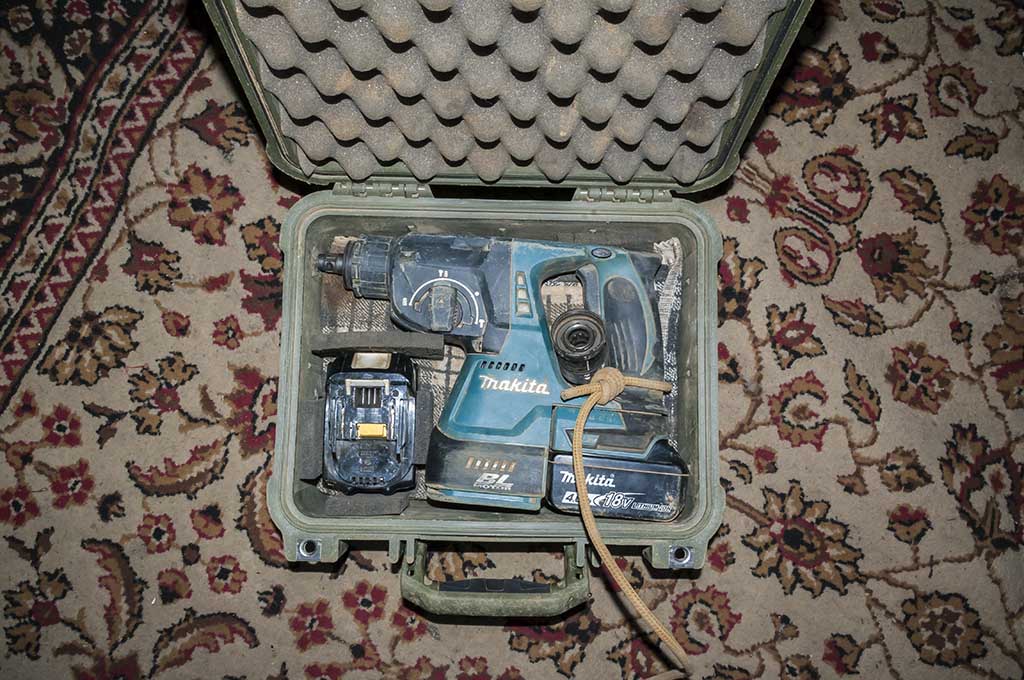

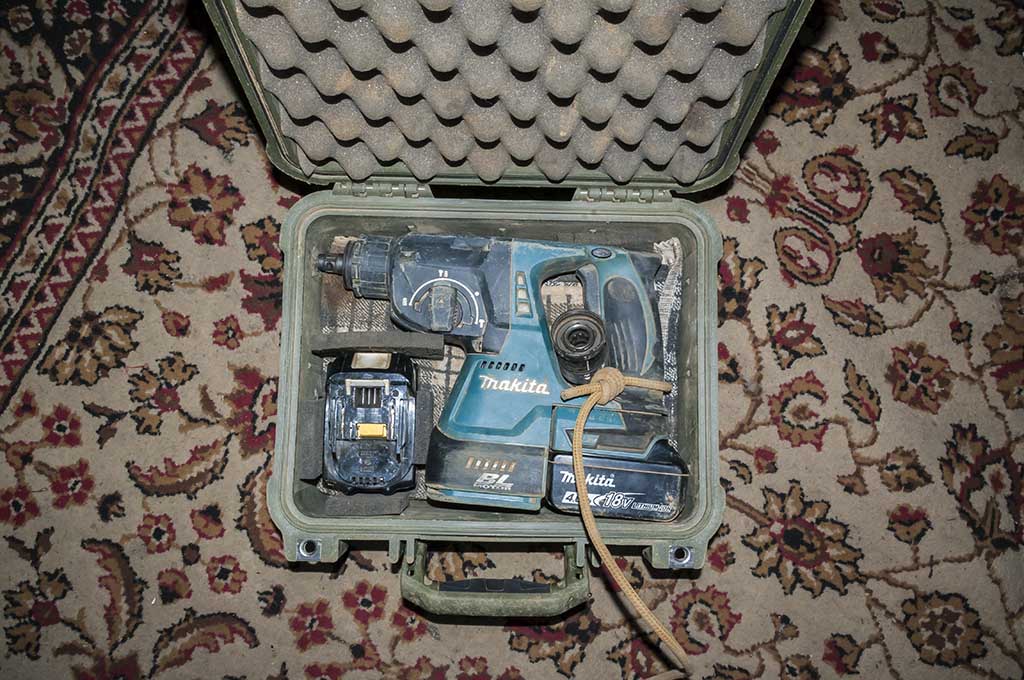

I got the same model as Sam, except it has a removable chuck (243 model), and comes with a normal 3-jaw chuck for 'normal' work - and it's a very high quality chuck indeed. This does mean that mine's a teensy bit longer than Sam's, so the chuck has to be removed before fitting in the Peli 1400 - and boy is it a snug fit - it can't even move with a battery on. The chisel option is very, very useful, and has removed a foot-thick slab of calcite in two sessions recently with no issues. I drilled 13 X 12mm holes last week to 150mm depth on a 5aH battery with no probs, though it was down to its last bar on the indicator. And despite its chunky appearance, it doesn't seem that heavy for bolting, even upwards, but then I am used to having heavy stuff hanging around, so it may vary from person to person what's comfortable.

How much consideration is given to actual drilling technique. Such as as a series of driil lengths . Using just one long drill you will invariably cause a bowing effect adding friction. Drilling a 1 metre deep hole is an entirely different ball game to drilling 10 x 10 cm holes . Another problem is the drill body flutes roughening with use,so impeeding dust removal. Has or does anyone used lubricants ?

Pitlamp

Well-known member

Useful advice there thomasr.

No, I don't use lubricants because when I tried them I found they cause dust to stick and increase friction. (That was liquid lubricants of course, such as good old WD40; admittedly I never tried solid lubricants such as graphite dust.)

Whenever I need to drill deep holes I usually have a small wire brush with me to clean the drill flutes periodically. Of all the things I've tried this seems to work most effectively.

No, I don't use lubricants because when I tried them I found they cause dust to stick and increase friction. (That was liquid lubricants of course, such as good old WD40; admittedly I never tried solid lubricants such as graphite dust.)

Whenever I need to drill deep holes I usually have a small wire brush with me to clean the drill flutes periodically. Of all the things I've tried this seems to work most effectively.

MJenkinson

Member

I think the issue with your liquid lubricants Pitlamp is the volume you would need to apply. I know offshore we always ran "mud" (drilling fluid) downhole to lift cuttings up and out (totally different scale of hole though!). Land coring rigs run mud as well. You would need a constant flush volume to make any difference and I have no idea how you would get this down the hole using a normal drill bit. You can get wet drilling coring drills but I have never seen a cordless one.

SamT

Moderator

thomasr said:How much consideration is given to actual drilling technique.

Another common error is to push way tooooooo hard on the back of the drill. As someone pointed out, the impact energy is generated by the mechanism within the drill. By pushing really really hard on the back of the drill, I suspect that you are quashing the ability of that mechanism to work effectively and efficiently. I once witnessed a build bloke at work pushing so hard on the back of the drill that he was practically stopping the drill from turning. (note, this was an SDS drill, not a 'hammer' action drill where reasonable force is needed).

Imagine you are drying to hammer a nail into a piece of wood, and someone comes along and tried to push your fore arm down, making it difficult for you to lift your arm up for another blow.

The end result is slow drilling, hot drill bits and rapidly depleted batteries.

Pitlamp

Well-known member

MJenkinson said:I think the issue with your liquid lubricants Pitlamp is the volume you would need to apply. I know offshore we always ran "mud" (drilling fluid) downhole to lift cuttings up and out (totally different scale of hole though!). Land coring rigs run mud as well. You would need a constant flush volume to make any difference and I have no idea how you would get this down the hole using a normal drill bit. You can get wet drilling coring drills but I have never seen a cordless one.

Ah - I see what you mean; I'd assumed thomasr meant a thin application of a lubricating substance rather than a large volume of flowing lubricant to remove the drilling dust (as in various larger scale industrial uses).

One of the reasons stardrills work so well underwater is that the drilling dust is flushed out by water during the back & forth movement of the stardrill itself.

Some regard this as stone age technology but, in the right circumstances, it's actually the best of several options. A certain ring bolt (which you'll soon be heading for whilst laying new line in a certain well known Dales underwater cave) was recently installed that way!

pwhole

Well-known member

From what I can gather, if used horizontally, the correct force used should be the same as if the tool were used vertically with only support - as in, just the weight of the tool. That's certainly true with the chisel action, which only really works properly if you don't push it. It's just about finding that sweet spot. I remember in the olden days when guys used to regularly dig up roads with pneumatic drills, and the thing would be just bouncing around like a pogo stick, but it still dug up the road without much effort.

A couple of years ago, I went through a similar problem and ended up with a Milwankee 12V drill. I did a gear review and test on it for the Chelsea Newsletter, but attach a copy it below. The right drill bit was important and some multipoint drills were slower than a good 2 point ones!

Attachments

Mattrees

Member

John S said:A couple of years ago, I went through a similar problem and ended up with a Milwankee 12V drill. I did a gear review and test on it for the Chelsea Newsletter, but attach a copy it below. The right drill bit was important and some multipoint drills were slower than a good 2 point ones!

This was really helpful.

Maxf - I did some testing with my Einhell/Ozito drill on a lump of Whitehead limestone (Oolite) in the garden, (local dolomite where I've used it underground, tends to be softer) and found around 30 secs with a two edged (6mm) bit and 40 with a four edged.

I got 18x 50mm holes from a 4ah battery, the ambient temperature was cooler than a typical UK cave.

Hope that's useful.

Mattrees said:John S said:A couple of years ago, I went through a similar problem and ended up with a Milwankee 12V drill. I did a gear review and test on it for the Chelsea Newsletter, but attach a copy it below. The right drill bit was important and some multipoint drills were slower than a good 2 point ones!

This was really helpful.

Maxf - I did some testing with my Einhell/Ozito drill on a lump of Whitehead limestone (Oolite) in the garden, (local dolomite where I've used it underground, tends to be softer) and found around 30 secs with a two edged (6mm) bit and 40 with a four edged.

I got 18x 50mm holes from a 4ah battery, the ambient temperature was cooler than a typical UK cave.

Hope that's useful.

Thanks Mattress that's very useful, not sure why but my Einhell fails to make any progress in 40 seconds let alone 400 seconds !

Will try to get a video for comparison once I'm home

PeteHall

Moderator

It won't fix your drill Max, but when we tested the hilti bits a few years ago, they did pretty much double for the same battery usage. Well worth the extra cost if it saves you having to buy (and carry down a cave) another battery!

And as a bonus, the hilti shop in Bristol is right next door to toolstation

And as a bonus, the hilti shop in Bristol is right next door to toolstation

pwhole

Well-known member

I've just been using a Milwaukee 18V SDS drill at work, and yesterday drilled 8 X 6mm holes, 100mm deep in damp old 60s concrete fascia panels, 50mm thick over brick, before the 5Ah battery ran out. As I was hanging on a rope from a parapet, with a trip downstairs to change the battery, this was frustrating. Last week, underground, my Makita did 12 X 14mm holes, 100 mm deep, in solid, homogenous and very hard limestone, and still had one bar left on the battery, but I'd finished the job. That's a real-world example.

Of course the work batteries have probably been misused to some degree and probably charged thoughtlessly, but even so, the drill itself didn't seem to have much 'impact' - its primary function, after all. And it's big and heavy. I have used my own drill at work before, but on this one, insurance wouldn't let me. A shame, as we'd be half a day ahead of where we are this week already.

Of course the work batteries have probably been misused to some degree and probably charged thoughtlessly, but even so, the drill itself didn't seem to have much 'impact' - its primary function, after all. And it's big and heavy. I have used my own drill at work before, but on this one, insurance wouldn't let me. A shame, as we'd be half a day ahead of where we are this week already.

andrewmcleod

Well-known member

pwhole said:Last week, underground, my Makita did 12 X 14mm holes, 100 mm deep, in solid, homogenous and very hard limestone, and still had one bar left on the battery, but I'd finished the job. That's a real-world example.

Which Makita, out of curiosity?

pwhole

Well-known member

It's the DHR243 - same as the 242, but with an additional 3-jaw chuck.

http://www.makitauk.com/products/cordless-tools/rotary-hammers/all-cordless-rotary-hammers/dhr243rmj-18v-rotary-hammer-sds-24mm.html

http://www.makitauk.com/products/cordless-tools/rotary-hammers/all-cordless-rotary-hammers/dhr243rmj-18v-rotary-hammer-sds-24mm.html

mch

Member

I never realised that you were so pedantic!pwhole said:Sorry - just noticed a typo too late to edit - that should have read 12 X 14mm holes, 100mm deep...

Mattrees said:John S said:A couple of years ago, I went through a similar problem and ended up with a Milwankee 12V drill. I did a gear review and test on it for the Chelsea Newsletter, but attach a copy it below. The right drill bit was important and some multipoint drills were slower than a good 2 point ones!

This was really helpful.

Maxf - I did some testing with my Einhell/Ozito drill on a lump of Whitehead limestone (Oolite) in the garden, (local dolomite where I've used it underground, tends to be softer) and found around 30 secs with a two edged (6mm) bit and 40 with a four edged.

I got 18x 50mm holes from a 4ah battery, the ambient temperature was cooler than a typical UK cave.

Hope that's useful.

So I rescued a block of rock from one of the caves I had tried the drill in, see here for the dismal results...

First video was a 6 mm two sided bit into the rock with very little progress then into the garage floor for comparison where it has no issues...

https://www.youtube.com/watch?v=4lE-ZNrhPkk

Second video same again, 6 mm bit but with four sides, slightly better but it doesn't seem to be working as well as yours Mattress !

https://www.youtube.com/watch?v=p3h6WCJ-SYU

(The drill is definitely in hammer mode and making some attempt at hammer action)